Note that the powder formation is controlled also by fluctuations phenomena in the supersaturated solution occurring during synthesis process. Hence, solvothermal synthesis proceeds generally, via three steps: first, the formation of a supersaturated solution, then nucleation, and finally nuclei growth. On the other hand, even though the surfactants have the ability to help in the growth of nanoparticles as well as their size and shape, the obtained materials might exhibit nonhomogeneity in their chemical composition and crystallinity. Thus, selection of appropriate surfactant type and amount is required, considering their determining role with respect to the chemical composition of the final product. The process provides an interesting template contribution as nanoreactors for the synthesis of nanoparticles with controllable diameter.

Indeed, the micellar structures are formed from self-assembling of surfactant molecules and yield to nanometre size droplets with insoluble cores and soluble shells. The use of surfactant, phase transferring agent, or templates such as silicon dioxide was found to help the control of molybdenum disulfide nanomaterials size and shape. The autoclave is maintained at an appropriate temperature and time needed to allow reaction process to occur following either one or two steps. As reported in our previous work, the preparation of molybdenum disulfide via the solvothermal method is quite easy and consists in mixing reactants in a Teflon-lined stainless steel autoclave filled with a solvent up to 40%–80% of its total volume. Īmong the most studied nanomaterials, molybdenum disulfide has shown interesting properties regarding various applications, among which it is used as wind turbines lubricants additive. On the other hand and as reported in our previous work, the solvothermal approach proves to be more eco-friendly in comparison with other technics. Its application was found to be efficient for obtaining a variety of structures, sizes, and morphologies that drew attention for applications in heterogeneous catalysis, electrochemistry, and tribology. The bottom-up approach is more advantageous than the top-down approach with respect to nanomaterial production, particularly, the solvothermal method. The top-down method consists in breaking down large pieces of material to generate the required nanostructures, whereas bottom-up approach implies assembling single atoms and molecules into larger nanostructures. As known, nanomaterials are obtained using various methods following bottom-up and top-down approaches. This technique was used afterward for the production of innovative nanomaterials of interest for different fields, such as catalysis and environment protection and energy, as well as medicine and mechanics. The technique was inspired from a natural production of many minerals in the earth’s crust under the conditions of high temperature and pressure permitting the formation of many minerals. The solvothermal synthesis is among the widely used methods for nanomaterials production through chemical reactions in a closed system involving appropriate solvent at temperatures higher than its boiling point. The obtained result showed that the approach adopted in the study might be of interest for further investigation of the process design and scaling-up. The sensitivity analysis revealed that the precursors have more significant impact on the obtained amount of molybdenum disulfide compared to hydrazine.

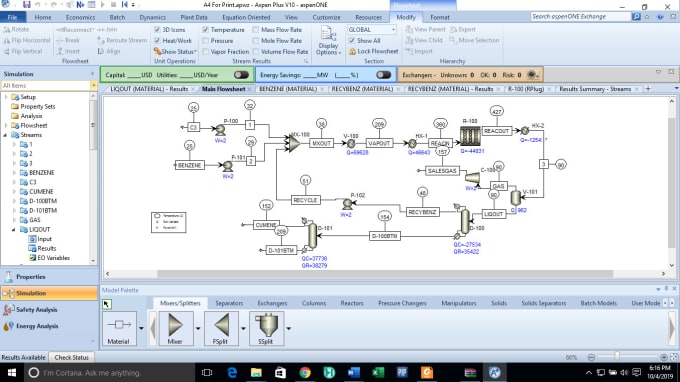

The adopted approach consists in simulating the synthesis process based on experimental data, obtained at laboratory scale followed by sensitivity analysis with respect to the following precursors: ammonium heptamolybdate, elemental sulfur, and hydrazine used as a reducing agent.

#Best journals for chemical process simulation plus#

The sensitivity analysis of molybdenum disulfide nanoparticles synthesis process is studied using Aspen Plus with the aim of investigating the effect of reactants’ amounts on the production of molybdenum disulfide nanoparticles.

0 kommentar(er)

0 kommentar(er)